Agv Robot Warehouse Montacargas Automatico Agv Logistics Whicle Automated Industrial Guided Guided Vehicles Precio Robot

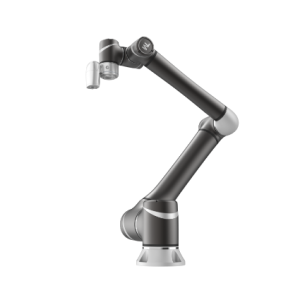

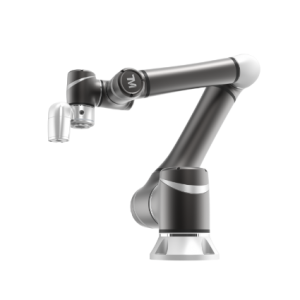

Agv50 50kg Load Capacity Collaborative Robot Agv Automated Guided Robot

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AGV AMR car for industrial material handling / China manufacturer AGV robot / warehouse AMR / AMR jack up lifting laser SLAM navigation / AGV AMR mobile robot / AGV AMR chassis laser SLAM navigation / intelligent logistic robot

Application

AMB Series Unmanned Chassis AMB (Auto Mobile Base) for agv autonomous vehicle, a universal chassis designed for agv autonomous guided vehicles, provides some features such as map editing and localization navigation. This unmanned chassis for agv cart provides abundant extent interfaces such as I/O and CAN to mount various upper modules together with powerful client software and dispatching systems to help users quickly complete manufacture and application of agv autonomous vehicles. There are four mounting holes on the top of the AMB series unmanned chassis for agv autonomous guided vehicles, which supports arbitrary expansion with jacking, rollers, manipulators, latent traction, display, etc. to achieve multiple applications of one chassis. AMB together with SEER Enterprise Enhanced Digitalization can realize the unified dispatching and deployment of hundreds of AMB products at the same time, which greatly improves the intelligent level of internal logistics and transportation in the factory.

Introducing our latest innovation in automated warehouse logistics: the AGV Robot Warehouse Montacargas Automático. This cutting-edge automated guided vehicle (AGV) is revolutionizing the way industrial warehouses operate by providing efficient and reliable transportation of goods.

The AGV Robot Warehouse Montacargas Automático is designed to seamlessly navigate through warehouse environments, transporting goods from one location to another with precision and accuracy. Equipped with advanced sensing and navigation technology, this AGV can safely maneuver around obstacles and navigate through narrow aisles, making it ideal for dynamic warehouse environments.

One of the key features of the AGV Robot Warehouse Montacargas Automático is its ability to integrate with existing warehouse management systems, allowing for seamless coordination with other equipment and processes. This integration streamlines warehouse operations and enhances overall efficiency, ultimately leading to cost savings and improved productivity.

In addition to its advanced navigation capabilities, the AGV Robot Warehouse Montacargas Automático is also designed with safety in mind. It is equipped with multiple layers of safety systems to ensure the protection of both the goods being transported and the workers in the warehouse.

Furthermore, the AGV Robot Warehouse Montacargas Automático is easy to install and requires minimal maintenance, making it a cost-effective solution for warehouses looking to automate their logistics operations. With its sturdy construction and reliable performance, this AGV is built to withstand the rigors of industrial warehouse environments, ensuring long-term durability and reliability.

Overall, the AGV Robot Warehouse Montacargas Automático is a game-changer for warehouse logistics, offering a highly efficient, safe, and reliable solution for the transportation of goods. With its advanced technology and seamless integration capabilities, this AGV is poised to transform the way warehouses operate, improving efficiency and productivity. Invest in the future of warehouse logistics with the AGV Robot Warehouse Montacargas Automático. Contact us today to learn more about this innovative solution.

Feature

·load capacity: 150kg & 300kg

·max. jacking height: 50mm

·navigation position accuracy: ±5mm

·navigation angle accuracy: ±0.5°

● Rich features available at any time

Comprehensive and excellent standard features and rich and practical advanced features help clients easily achieve intelligent logistics.

● Multi-specification platforms available for expansion

Provide 150kg and 300kg platforms to meet the load and scene requirements of different industries. It can also be used with manipulators, rollers, jacking, latent traction, pan/tilt, display screen, etc. to achieve multiple applications with one chassis.

● ±5 mm, efficient and accurate

Laser SLAM algorithm is used to achieve high-precision localization, with the laser non-reflective repeated locating accuracy within ±5 mm, enabling seamless docking between mobile robots and humans, and efficient flow of cargoes among various points. Note: Actual values depend on environmental conditions

● Stable navigation for safety and reliability

Laser SLAM navigation, laser reflector navigation, QR code navigation and other navigation methods are perfectly integrated and seamlessly switched to ensure the stable work of the mobile robot.

● Easy deployment and visible management

A full range of supporting software and digital systems can easily realize the operation, scheduling and information management of mobile robots, and seamlessly connect with the factory's MES system to truly realize smart logistics.

Related Products

Specification Parameter

Our Business