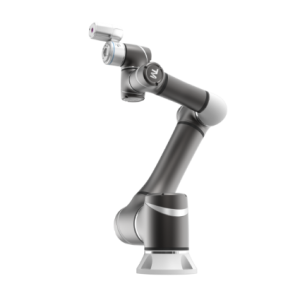

SCARA ROBOTIC ARMS – Z-Arm-4160 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent actuator/Automation solutions

Application

SCIC Z-Arm cobots are lightweight 4-axis collaborative robots with drive motor built inside, and no longer require reducers like other traditional scara, reducing the cost by 40%. SCIC Z-Arm cobots can realize functions including but no limited to 3D printing, material handling, welding, and laser engraving. It is capable of greatly improving the efficiency and flexibility of your work and production.

Features

High Precision

Repeatability

±0.05mm

Z-axis Customization

0.1-1m

Large Arm Span

J1 axis 325m

J2 axis 275m

Competive Price

Industrial-level quality

Competitive price

Easy to Program, Fast to Install, Flexible 4-Axis Robot Arm

High Precision

Repeatability: ±0.05mm

Big Arm Span

J1-Axis: 325mm, J2-Axis: 275mm

Customized Z-Axis

The up-down stroke can be customized between 10cm-1.0m

Space-Saving

Drive/Controller is Built-in

Simple and Easy to use

The newcomer who didn't know robot arm also can be easy to use, the interface is opening.

High Speed

Its speed is 1500mm/s under the load of 3kg

Related Products

Specification Parameter

The SCIC Z-Arm 4160 is designed by SCIC Tech, it is lightweight collaborative robot, easy to program and use, support SDK. In addition, it is collision detection supported, namely, it would be automatic to stop when touching human, which is smart human-machine collaboration, the security is high.

|

Z-Arm 4160 Collaborative Robot arm |

Parameters |

|

1 axis arm length |

325mm |

|

1 axis rotation angle |

±90° |

|

2 axis arm length |

275mm |

|

2 axis rotation angle |

±164° Optional: 15-345deg |

|

Z axis stroke |

410 Height can be customized |

|

R axis rotation range |

±1080° |

|

Linear speed |

1500mm/s (payload 3kg) |

|

Repeatability |

±0.05mm |

|

Standard payload |

3kg |

|

Maximum payload |

3.5kg |

|

Degree of freedom |

4 |

|

Power supply |

220V/110V50-60HZ adapt to 48VDC peak power 960W |

|

Communication |

Ethernet |

|

Expandability |

Built-in integrated motion controller provides 24 I/O + under-arm expansion |

|

Z-axis can be customized in height |

0.1m~1m |

|

Z-axis dragging teaching |

/ |

|

Electrical interface reserved |

Standard configuration: 24*23awg (unshielded) wires from the socket panel through the lower arm cover Optional: 2 φ4 vacuum tubes through the socket panel and flange |

|

Compatible HITBOT electric grippers |

Z-EFG-8S/Z-EFG-12/Z-EFG-20/Z-EFG-20S/Z-EFG-20F/Z-ERG-20C/Z-EFG-30/Z-EFG-50/Z-EFG-100/the 5th Axis, 3D printing |

|

Breathing light |

/ |

|

Second arm range of motion |

Standard: ±164° Optional: 15-345deg |

|

Optional accessories |

/ |

|

Use environment |

Ambient temperature: 0-45°C Humidity: 20-80%RH (no frost) |

|

I/O port digital input (isolated) |

9+3+forearm extension (optional) |

|

I/O port digital output (isolated) |

9+3+forearm extension (optional) |

|

I/O port analog input (4-20mA) |

/ |

|

I/O port analog output (4-20mA) |

/ |

|

Robot arm height |

830mm |

|

Robot arm weight |

410mm stroke net weight 28.5kg |

|

Base size |

250mm*250mm*15mm |

|

Distance between base fixing holes |

200mm*200mm with four M8*20 screws |

|

Collision detection |

√ |

|

Drag teaching |

√ |

Ideal Selection for Lightweight Assembly Tasks

Z-Arm XX60 is a 4-axis robot arm with big arm span, occupying small area, very suitable to put on work station or inside machine, it is an ideal selection for lightweight assembly task.

Lightweight with Big Rotation Angle

The product weight is about 28.5kg, its max load can be up to 3.5kg, the rotation angel of 1-axis is ±90°, the rotation angle of 2-axis is ±164°, the rotation range of R-axis can be up to ±1080°.

Big Arm Span, Wide Application

Z-Arm XX60 has a long arm span, the length of 1-axis is 325mm, the length of 2-axis is 275mm, its linear speed can be up to 1500mm/s under the load of 3kg.

Flexible to Deploy, Fast to Switch

The Z-Arm XX60 has the characteristics of lightweight, space-saaving and flexible to deploy, it is suitable to deploy in many applications, and it would not change the former production layout, including fast to switch process sequence and complete small batch of production, etc.

DragTeaching to Complete Program

The software is base on graphic design, it has provided point, output signal, electric gripper, tray, delayed, sub-process, reset and other basic functional module, users can drag module to control robot arm in programming area, the interface is simple, but function is powerful.

Motion Range M1 Version (Rotate Outwards)

DB15 Connector Recommendation

Recommended model: Gold-plated male with ABS shell YL-SCD-15M Gold-plated female with ABS shell YL-SCD-15F

Size Description: 55mm*43mm*16mm

(Refer to Figure 5)

Diagram of The External Use Environment of The Robot Arm

Our Business

-300x2551-300x300.png)