Good Quality China Suppliers Cheap Collaborative Robotic Cobot Arm

Good Quality China Suppliers Cheap Collaborative Robotic Cobot Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent actuator/Automation solutions

Application

SCIC Z-Arm cobots with its high automation & sound precision, can free workers from repetitive and fatigue work in various industries and applications, including but not limited to:

- Assembly: screwdriving, part insertion, spot welding, soldering, etc.

- Materials handling: pick and place, grinding, drilling, etc.

- Dispensing: gluing, sealing, painting, etc.

- inspection and testing, as well as school education.

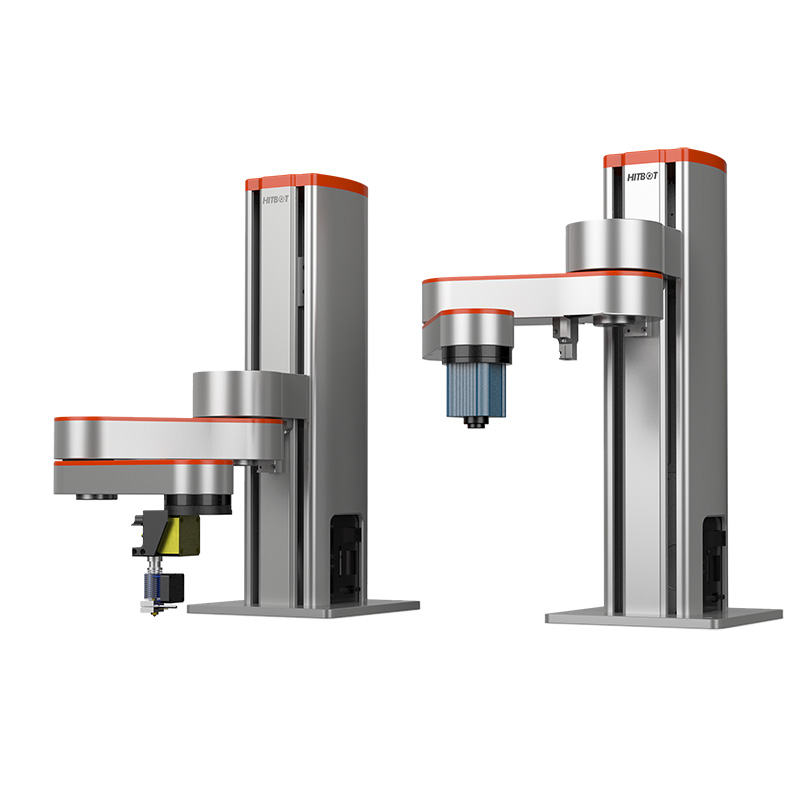

Introducing our latest breakthrough in robotics - the high-quality desktop small 4-axis Scara industrial robot arm. This compact yet powerful robotic arm is designed to revolutionize industrial automation by delivering unparalleled precision, efficiency and flexibility.

The high quality desktop small 4-axis Scara industrial robot arm is carefully crafted using the highest quality materials and components to ensure its durability and reliability for long-term use. Its compact size makes it ideal for use in tight spaces without compromising its functionality. Featuring a 4-axis design, the robotic arm can perform complex movements with extreme precision, allowing it to handle a variety of tasks with ease.

The high-quality desktop small 4-axis Scara industrial robot arm is equipped with advanced programming capabilities to integrate seamlessly into existing manufacturing processes. Its user-friendly interface can be easily programmed and customized, ensuring fast and efficient setup without the need for extensive technical expertise. This not only saves valuable time but also increases productivity, making it an ideal solution for various industries such as electronics, automotive, pharmaceuticals and more.

One of the outstanding features of our high-quality desktop small 4-axis Scara industrial robot arm is its exceptional speed and precision. With its high load capacity and fast arm movements, it can handle precision parts and perform complex tasks with the highest precision, significantly reducing the risk of errors and improving overall production quality. This ensures consistent and reliable performance, minimizing downtime and maximizing production.

Features

High Precision

Repeatability

±0.02mm

Z-axis Customization

0.1-0.5m

Large Arm Span

JI axis 160mm

J2 axis 160mm

Competive Price

Industrial-level quality

Competitive price

Lightweight Colla borative Robot

Z-Arm XX32 is a smal collaborative four axes robot arm, small area covering, very suitable to put on work desk or built-in machinery, it is an ideal seleection for lightweight assembly task.

Lightweight, Big Rotation Angle

The product weight is about 11kg, the big load can reach 1kg, the rotation angle of 1 axis is ±90°, 2 axis is ±143°, the rotation range of R axis can be up to ±1080°.

Flexibe to Deploy, Fast to Switch

Z-Arm XX32 is lightweight and flexible, saving work space, flexible to deploy, it is suitable to dispose on many apps without changing your original setting, including fast to switch work procedure and complete small batch of production, etc.

Friendly Collaborative and Security

It can be collaborative to work with human without fence to isolate, to complete the dirty, danger and boring task, to reduce repeat work strain and accidental injury.

Related Products

Specification Parameter

SCIC Z-Arm 1832 is a 4-aixs collaborative robotic arm with 180mm travel reaching of Z axis and 320mm arm reach.

Compact and Precise.

Flexible to deploy in various application scenarios.

Simple but Versatile.

Easy to program and use, handheld teaching programming, SDK secondary development supported.

Collaborative and Safe.

Collision detection supported, smart human-machine collaboration.

Z-Arm 1832 is a small collaborative four axes robot arm, small area covering, very suitable to put on work desk to built-in machinery, it is an ideal selection for lightweight assembly task.

Z-Arm 1832 is lightweight and flexible, saving work space, flexible to deploy, it is suitable to dispose on many apps without changing your original setting, including fast to switch work procedure and complete small batch of production, etc. It can be collaborative to work with human without fence to isolate, to complete the dirty, danger and boring task, to reduce repeat work strain and accidental injury.

|

Z-Arm XX32 Collaborative Robot arm |

Parameters |

|

1 axis arm length |

160mm |

|

1 axis rotation angle |

±90° |

|

2 axis arm length |

160mm |

|

2 axis rotation angle |

±143° |

|

Z axis stroke |

Height can be customized |

|

R axis rotation range |

±1080° |

|

Linear speed |

1017mm/s (payload 0.5kg) |

|

Repeatability |

±0.02mm |

|

Standard payload |

0.5kg |

|

Maximum payload |

1kg |

|

Degree of freedom |

4 |

|

Power supply |

220V/110V50-60HZ adapt to 24VDC peak power 320W |

|

Communication |

Ethernet |

|

Expandability |

Built-in integrated motion controller provides 24 I/O |

|

Z-axis can be customized in height |

0.1m-0.5m |

|

Z-axis dragging teaching |

/ |

|

Electrical interface reserved |

/ |

|

Compatible HITBOT electric grippers |

Z-EFG-8S/Z-EFG-20 |

|

Breathing light |

/ |

|

Second arm range of motion |

Standard:±143° |

|

Optional accessories |

/ |

|

Use environment |

Ambient temperature: 0-55°C Humidity: RH85 (no frost) |

|

I/O port digital input (isolated) |

9+3 |

|

I/O port digital output (isolated) |

9+3 |

|

I/O port analog input (4-20mA) |

/ |

|

I/O port analog output (4-20mA) |

/ |

|

Robot arm height |

500mm |

|

Robot arm weight |

180mm stroke net weight 11kg |

|

Base size |

200mm*200mm*10mm |

|

Distance between base fixing holes |

160mm*160mm with four M5*12 screws |

|

Collision detection |

√ |

|

Drag teaching |

√ |

Safety is paramount and our high quality desktop small 4-axis Scara industrial robot arm is designed with this in mind. Equipped with advanced sensor technology and comprehensive safety features to ensure safe operation in any working environment. This gives the operator peace of mind and minimizes the risk of accident or injury.

In short, our high-quality desktop small 4-axis Scara industrial robot arm will revolutionize the field of industrial automation. With its compact size, superior accuracy and advanced programming capabilities, it provides an unparalleled solution for streamlining manufacturing processes, increasing productivity and improving overall efficiency. Invest in our high-quality desktop small 4-axis Scara industrial robot arm and experience the future of automation today.

Motion Range and Dimensions

Remark: There is a cable below the robot arm, which is not shown in the figure, please refer to the actual product.

Interface Introduction

The Z-Arm 1832 robot arm interface is installed in 2 locations, the back of the robot arm base (defined as A) and the bottom of the last arm(defined as B).The interface panel at A has a power switch interface (J1), 24V power supply interface DB2 (J2), output to user I/O port DB15 (J3), user input I/O port DB15 (J4) and IP address configuration buttons(K5), ethernet port (J6), system input/output port (J7).The interface panel B has a I/O aviation socket for controlling electric grippers.

Precautions

1. Payload inertia

The payload center of gravity and the recommended payload range with the Z axis movement inertia are shown in Figure 1.

Figure1 XX32 series payload description

2. Collision force

Trigger force of horizontal joint collision protection: the force of XX32 series is 30N.

3. Z-axis external force

The external force of the Z axis shall not exceed 100N.

Figure 2

4. Notes for installation of customized Z axis, see Figure 3 for details.

Figure 3

Warning Note:

(1) For customized Z-axis with a large stroke, The Z-axis rigidity decreases as the stroke increases. When the Z-axis stroke exceeds the recommended value, the user has the rigidity requirement, and the speed is >50% of the maximum speed, it is highly recommended to install a support behind the Z-axis to ensure that the rigidity of the robot arm meets the requirement at high speed.

The recommended values are as follows:

Z-ArmXX32 series Z-axis stroke >500mm

(2) After the Z-axis stroke is increased, the verticality of Z-axis and the base will be greatly reduced. If strict verticality requirements for the Z-axis and the base reference are not applicable, please consult the technical personnel separately.

5.Power cable hot-plugging forbidden. Reverse warning when the positive and negative poles of the power supply are disconnected.

6. Do not press down the horizontal arm when the power is off.

Figure 4

DB15 Connector Recommendation

Figure 5

Recommended model: Gold-plated male with ABS shell YL-SCD-15M Gold-plated female with ABS shell YL-SCD-15F

Size Description: 55mm*43mm*16mm

(Refer to Figure 5)

Robot Arm Compatible Grippers Table

|

Robot Arm Model No. |

Compatible Grippers |

|

XX32 |

Z-EFG-8S NK/Z-EFG-20 NM NMA |

Power Adapter Installation Size Diagram

XX32 configuration 24V 500W RSP-500-SPEC-CN power supply

Diagram of The External Use Environment of The Robot Arm

Our Business