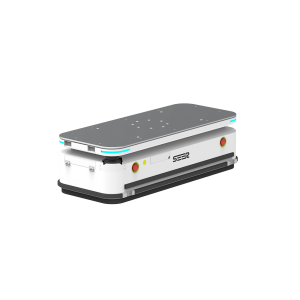

STANDARD AMRS – Auto Mobile Bases AMB-150/AMB-150-D

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AGV AMR car for industrial material handling / China manufacturer AGV robot / warehouse AMR / AMR jack up lifting laser SLAM navigation / AGV AMR mobile robot / AGV AMR chassis laser SLAM navigation / intelligent logistic robot

Application

AMB Series Unmanned Chassis AMB (Auto Mobile Base) for agv autonomous vehicle, a universal chassis designed for agv autonomous guided vehicles, provides some features such as map editing and localization navigation. This unmanned chassis for agv cart provides abundant extent interfaces such as I/O and CAN to mount various upper modules together with powerful client software and dispatching systems to help users quickly complete manufacture and application of agv autonomous vehicles. There are four mounting holes on the top of the AMB series unmanned chassis for agv autonomous guided vehicles, which supports arbitrary expansion with jacking, rollers, manipulators, latent traction, display, etc. to achieve multiple applications of one chassis. AMB together with SEER Enterprise Enhanced Digitalization can realize the unified dispatching and deployment of hundreds of AMB products at the same time, which greatly improves the intelligent level of internal logistics and transportation in the factory.

Feature

· Rated Load: 150kg

· Run Time: 12h

· Lidar Number: 1 or 2

· Rotation Diameter: 840mm

· Navigation Speed: ≤1.4m/s

· Positioning Accuracy: ±5,0.5mm

● Universal Chassis, Flexible Expansion

Four mounting holes are set above the chassis, providing rich interfaces to mount various upper structures such as lifting mechanisms, rollers, robotic arms, latent traction, and pan-tilt systems.

● Multiple Navigation Methods, Positioning Accuracy Up to ±2 mm

Laser SLAM, laser reflector, QR code, and other navigation methods are perfectly integrated, achieving a repeated positioning accuracy up to ±2 mm. This allows precise docking between AMR and equipment, enabling efficient material handling.

● High Cost-effective, Reduce Costs and Improve Efficiency

The highly cost-effective universal AMR platform, with precise cost reduction and efficiency improvement, is an excellent choice for customers to manufacture various types of mobile robots.

● Strong Optimized Software, More Supplied Functions

Based on the SEER Robotics' complete system software, it is easy to achieve full factory AMR deployment, dispatching, operation, information management, etc., and can seamlessly connect with the factory MES system, making the entire process smoother.

Specification Parameter

|

Product model |

AMB-150 / AMB-150-D |

AMB-300 / AMB-300-D |

AMB-300XS |

|

|

Basic parameters |

Navigation method |

Laser SLAM |

Laser SLAM |

Laser SLAM |

|

Drive mode |

Two-wheel differential |

Two-wheel differential |

Two-wheel differential |

|

|

Shell color |

Pearl white / Pearl black |

Pearl white / Pearl black |

RAL9003 |

|

|

L*W*H(mm) |

800*560*200 |

1000*700*200 |

842*582*300 |

|

|

Rotation diameter(mm) |

840 |

1040 |

972.6 |

|

|

Weight (with battery)(kg) |

66 |

144 |

120 |

|

|

Load capacity(kg) |

150 |

300 |

300 |

|

|

Minimum passable width(mm) |

700 |

840 |

722 |

|

|

Performance parameters |

||||

|

Navigation position accuracy(mm*) |

±5 |

±5 |

±5 |

|

|

Navigation angle accuracy(°) |

±0.5 |

±0.5 |

±0.5 |

|

|

Navigation speed(m/s) |

≤1.4 |

≤1.4 |

≤1.5 |

|

|

Battery parameters |

Battery specifications(V/Ah) |

48/35 (Ternary lithium) |

48/52 (Ternary lithium) |

48/40 (Ternary lithium) |

|

Comprehensive battery life(h) |

12 |

12 |

12 |

|

|

Charging time(10-80%)(10-80%)(h) |

≤2 |

≤ 2.5 |

≤ 2.5 |

|

|

Charging method |

Manual/Automatic/Switch |

Manual/Automatic/Switch |

Manual/Automatic/Switch |

|

|

Extended interfaces |

Power DO |

Seven-Way (total load capacity 24V/2A) |

Seven-Way (total load capacity 24V/2A) |

Three-Way (total load capacity 24V/2A) |

|

DI |

Ten-Way (NPN) |

Ten-Way (NPN) |

Eleven-Way (PNP/NPN) |

|

|

E-stop interface |

Two-Way output |

Two-Way output |

Two-Way output |

|

|

Wired network |

Three-Way RJ45 gigabit ethernet |

Three-Way RJ45 gigabit ethernet |

Two-Way M12 X-Code gigabit ethernet |

|

|

Configurations |

Lidar number |

1 or 2 |

1 or 2 |

2(SICK nanoScan3) |

|

HMI display |

● |

● |

- |

|

|

E-stop button |

● |

● |

● |

|

|

Buzzer |

● |

● |

- |

|

|

Speaker |

● |

● |

● |

|

|

Ambient light |

● |

● |

● |

|

|

Bumperstrip |

- |

- |

● |

|

|

Functions |

Wi-Fi roaming |

● |

● |

● |

|

Automatic charging |

● |

● |

● |

|

|

Shelf recognition |

● |

● |

● |

|

|

Laser reflector navigation |

〇 |

〇 |

〇 |

|

|

3D obstacle avoidance |

〇 |

〇 |

〇 |

|

|

Certifications |

ISO 3691-4 |

- |

- |

● |

|

EMC/ESD |

● |

● |

● |

|

|

UN38.3 |

● |

● |

● |

|

|

Cleanliness |

- |

ISO Class 4 |

ISO Class 4 |

|

* Navigation accuracy usually refers to the repeatability accuracy that a robot navigates to the station.

● Standard 〇 Optional None

Our Business