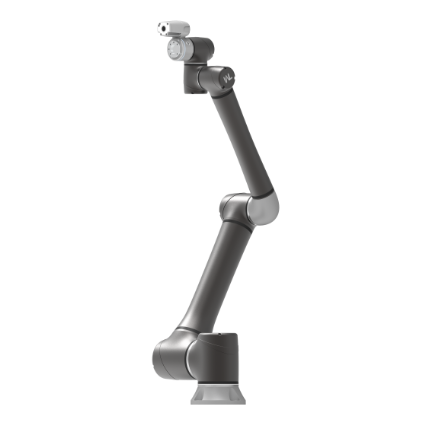

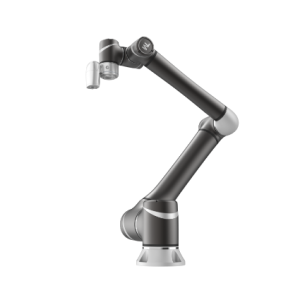

Welding Robot Arm with Control Cabinet 6 Axis, Range 1300mm, Payload 20kg Industrial Robot

Welding Robot Arm with Control Cabinet 6 Axis, Range 1300mm, Payload 20kg Industrial Robot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent actuator/Automation solutions

Application

The TM20 has a higher payload capability in our AI robot series. The increased payload of up to 20kg, enables the further scaling of robotic automation and throughput increases for more demanding, heavier-duty applications with ease. It is specifically designed for massive pick-and-place tasks, heavy machine tending, and high-volume packaging and palletizing. TM20 is suitable for a wide range of applications in almost all industries.

With a class-leading vision system, advanced AI technology, comprehensive safety, and easy operation, AI Cobot will take your business further than ever. Take automation to the next level by boosting productivity, improving quality, and reducing costs.

Introducing our innovative and efficient 6-axis robotic arm, designed to revolutionize industrial processes such as loading and unloading, polishing, handling, spraying, inverter welding, and flame cutting. With state-of-the-art technology and advanced automation features, this versatile robotic arm offers unparalleled precision and productivity.

The loading and unloading capabilities of our robotic arm streamline the manufacturing process by quickly and accurately transferring materials and products between different stages of production. Whether it's placing components on a conveyor belt or picking up finished goods from a production line, this robotic arm excels in optimizing logistics and reducing manual labor.

In the realm of polishing, our robotic arm's precision control and meticulous movements ensure a flawless finish on various surfaces. Its programmed movements replicate the intricacies of human hand detailing with unparalleled accuracy and consistency, resulting in high-quality products that meet the most demanding quality standards.

Handling heavy and bulky materials is made effortless with the robotic arm's lifting capabilities. Equipped with advanced sensors and powerful motors, it can effortlessly maneuver objects of varying shapes and sizes, reducing the risk of injury and increasing efficiency in industrial environments.

Spraying tasks become more precise and consistent with the integrated sprayer mounted on the robotic arm. Whether it's painting intricate designs on complex structures or evenly coating large surfaces, this robotic arm ensures a uniform and professional finish, minimizing wastage and maximizing resource utilization.

Inverter welding, a crucial process in many industries, is made more efficient and reliable with our robotic arm. With the ability to replicate complex welding patterns, the arm delivers consistent and high-quality welds, reducing human error and increasing productivity.

Furthermore, the flame cutting capabilities of this robotic arm allow for accurate and efficient metal cutting, eliminating the need for manual labor and increasing safety in hazardous environments.

Our robotic arm is equipped with advanced inverter technology and intelligent control systems, ensuring energy efficiency and precise movements. This translates into significant cost savings and increased productivity for industrial operations.

In conclusion, our 6-axis robotic arm is a game-changer in the industrial sector, offering a wide range of capabilities that enhance various processes. With unmatched precision, efficiency, and versatility, this robotic arm empowers businesses to achieve superior results, save costs, and stay ahead in the ever-evolving manufacturing landscape.

Features

SMART

Future-proof Your Cobot with AI

• Automated optical inspection (AOI)

• Quality assurance & consistency

• Increase production efficiency

• Reduce operating costs

SIMPLE

No experience required

• Graphical interface for easy programming

• Process-oriented editing workflow

• Simple hand guiding for positions teaching

• Fast visual calibration with calibration board

SAFE

Collaborative safety is our priority

• Complies with ISO 10218-1:2011 & ISO/TS 15066:2016

• Collison detection with emergency stop

• Save the cost and space for barriers & fencing

• Set up speed limits in a collaborative workspace

AI-powered cobots recognize the presence and orientation of their environment and parts to perform visual inspections and dynamic pick-and-place tasks. Effortlessly apply AI to the production line and increase productivity, decrease costs, and shorten cycle times. AI vision can also read results from machines or test equipment and make appropriate decisions accordingly.

Besides improving automation processes, an AI-driven cobot can track, analyze, and integrate data during production to prevent defects and improve product quality. Easily enhance your factory automation with a complete set of AI technology.

Our collaborative robots are equipped with an integrated vision system, giving cobots the ability to perceive their surroundings which significantly enhances cobot capabilities. Robot vision or the ability to “see” and interpret visual data into command prompts is one of the features that makes us superior. It is a game-changer for accurately performing tasks in dynamic changing workspaces, making operations run smoother, and automation processes more efficiently.

Designed with first-time users in mind, programming knowledge is not a prerequisite to get started with AI Cobot. An intuitive click-and-drag motion using our flow programming software reduces the complexity. Our patented technology allows operators with no coding experience to program a project as short as five minutes.

Inherent safety sensors will stop AI Cobot when physical contact is detected, minimizing the potential damage for a pressure-free and safe environment. You can also set up speed limits for the robot so it can be used in a variety of environments right next to your workers.

Related Products

Specification Parameter

|

Model |

TM20 |

|

|

Weight |

32.8KG |

|

|

Maximum Payload |

20KG |

|

|

Reach |

1300mm |

|

|

Joint Ranges |

J1,J6 |

±270° |

| J2,J4,J5 |

±180° |

|

| J3 | ±166° | |

|

Speed |

J1,J2 |

90°/s |

| J3 |

120°/s |

|

| J4 |

150°/s |

|

| J5 |

180°/s |

|

| J6 |

225°/s |

|

|

Typical Speed |

1.1m/s |

|

|

Max. Speed |

4m/s |

|

|

Repeatability |

± 0.1mm |

|

|

Degree of freedom |

6 rotation joints |

|

|

I/O |

Control box |

Digital input:16 Digital output:16 Analog input:2 Analog output:1 |

| Tool Conn. |

Digital input:4 Digital output:4 Analog input:1 Analog output:0 |

|

|

I/O Power Supply |

24V 2.0A for control box and 24V 1.5A for tool |

|

|

IP Classification |

IP54(Robot Arm); IP32(Control Box) |

|

|

Power Consumption |

Typical 300 watts |

|

|

Temperature |

The robot can work in a temperature range of 0-50℃ |

|

|

Cleanliness |

ISO Class 3 |

|

|

Power Supply |

100-240 VAC, 50-60 Hz |

|

|

I/O Interface |

3xCOM, 1xHDMI, 3xLAN, 4xUSB2.0, 2xUSB3.0 |

|

|

Communication |

RS232, Ethemet, Modbus TCP/RTU (master & slave), PROFINET (Optional), EtherNet/IP(Optional) |

|

|

Programming Environment |

TMflow, flowchart based |

|

|

Certification |

CE, SEMI S2 (Option) |

|

|

AI & Vision*(1) |

||

|

AI Function |

Classification, Object Detection, Segmentation, Anomaly Detection, AI OCR |

|

|

Application |

Positioning, 1D/2D Barcode Reading, OCR, Defect Detection, Measurement, Assembly Check |

|

|

Positioning Accuracy |

2D Positioning: 0.1mm*(2) |

|

|

Eye in Hand (Built in) |

Auto-focused color carmera with 5M resolution, Working distance 100mm ~ ∞ |

|

|

Eye to Hand (Optional) |

Support Maximum 2xGigE 2D cameras or 1xGigE 2D Camera +1x3D Camera*(3) |

|

| *(1) No built-in vision robot arms TM12X, TM14X, TM16X, TM20X are also available.

*(2) The data in this table are measured by TM laboratory and the working distance is 100mm. It should be noted that in practical applications, the relevant values may be different due to factors such as the on-site ambient light source, object characteristics, and vision programming methods that will affect the change in accuracy. *(3)Refer to the official website of TM Plug & Play for camera models compatible to TM Robot. |

||

Our Business